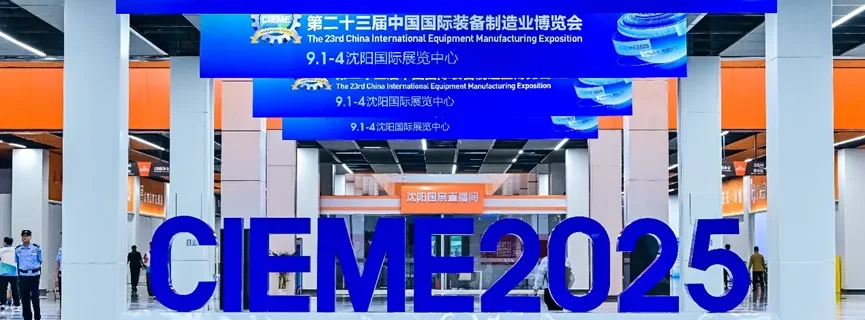

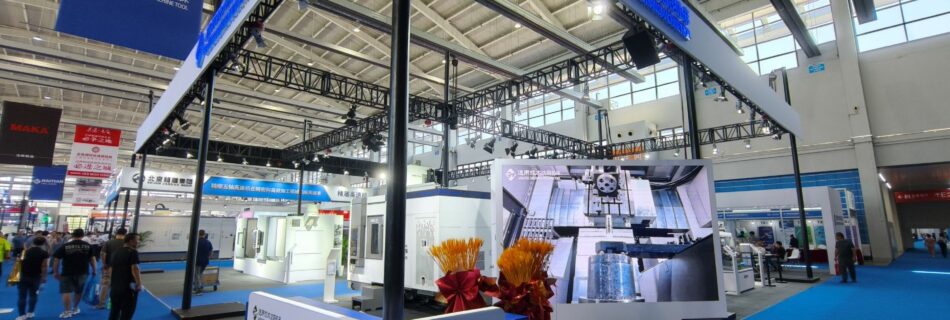

we take you behind the scenes at Shenyang First Machine Tool Factory to experience the intense atmosphere as the company accelerates towards the fourth quarter and strives to achieve its annual goals. With the year drawing to a close, the team at Shenyang Machine Tool is working tirelessly to meet tight delivery schedules and ensure on-time deliveries to key customers. Through continuous product upgrades and refined production processes, the company has not only seen significant order growth but is also facing a peak delivery period in the fourth quarter.

We speak with the factory staff and management to learn how they are ensuring product quality and delivery progress during this busy year-end period while celebrating their impressive achievements.

📈 Key Highlights of This Year:

A 19% increase in contract value

Significant growth in sales revenue and profitability

Multiple orders set for on-time delivery in the fourth quarter

At Shenyang Machine Tool, we witness a team full of energy and determination, working hard towards their goal with clarity and purpose. They are pushing forward to meet their annual objectives and look ahead to a brighter future.

🔔 Subscribe to our channel for the latest updates and industry insights from Shenyang Machine Tool!